FILTERS FROM WIRE MESH PERMEABLE MATERIAL (WMPM) Designed for performance and reliability in critical applications and harsh environments.

Design philosophy

Filter medium is made of compressed Wire Mesh Permeable Material (WMPM).The WMPM material manufactured by cold plastic deformation (no welding or brazing). This creates a wire mesh whose porous system is "open in all directions" and provides the required mechanical, physical, and hydrodynamic parameters, unlike the traditional wedge wire filters.

This design feature results in large working filtration surface area in small volume which reduces size of the unit and significantly increases time between cleaning cycles. Only several external layers utilized during filtration for the filter element design for back wash operation (not a volumetric filter).

Wire mesh is structured to create crescent shaped slots, so particle can travel along slot till s

top without being pressed and locked between wires. This minimizes particle obstruction, prevents filter cake formation and helps during back wash cleaning. The coils of wire of the WMPM filter form a lattice and are not fixed, so the coils can move relative to each other, displacing particles and letting them loose.

The filter element structure is flexible and elastic and allows shrinkage of the slots during filtration and expansion of the slots during cleaning which improves quality of filtration and regeneration of the filter to original condition after back flushing. Differential pressure across filtering element created during cleaning cycle causes the filter elements to expand (elasticity of WMPM), release particles and regenerate the filter.

Filter elements assembly can be designed to utilize differential pressure across filter to compress and expand filtering element not only in radial direction, but also axially which will provide additional increase in performance and regeneration.

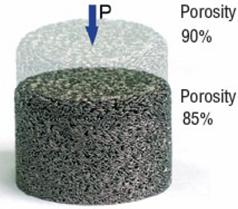

The essential WMPM feature is its elastic deformation properties, which allowchanges in porosity by varying the pressure load as shown in the pressure (P) vs.Porosity (S) in Figure 15. During filtration operation (pressure from outside to inside)the element porosity reduces, enhancing filtration efficiency and during leaningoperation (pressure from inside to outside) the porosity increases, improving theremoval of captured particles and causing effective mesh regeneration. The elasticproperties of the WMPM filter elements result in a low sensitivity to mechanical andthermal shock

Cleaning and Back Washing

The filter element structure is flexible and elastic and allows shrinkage of the slots during filtration and expansion of the slots during cleaning which improves quality of filtration and regeneration of the filter to original condition after back flushing. Differential pressure across filtering element created during cleaning cycle causes the filter elements to expand (elasticity of WMPM), release particles and regenerate the filter. Low flow rates for back flushing can be used due to expansion of the slots and release of the particles.

The cleaning operation is reverse flow at the same flow rate as filtration flow rate. The filter doesn't require any internal moving parts like suction scanners or filter candle selector valves. Thus it reduces the failures caused by mechanical components wear and fatigue over time, resulting in high reliability.

Back flushing does not affect the degradation of filter elements over time, so the lifeof filter elements is not limited by number of cycles. Longer filtering operationsbetween cleaning cycles reduce total number of cycles required during design life.

Material

The initial material for compressed wire mesh filters is metal wire of the required grade (Grade of the material is selected for application) and diameter (0.03–2.5 mm).

- Stainless steel

- Duplex and Super Duplex steel

- Inconel

- Monel

- Others

Shape

Filter element can be designed and formed in variety of shapes to fit desired housing and meet application requirements.

Design Considerations

For applications with flow rates from 10 GPM to 20,000 BPD the single filtration unit is provided. Filtration candles assembled from standard cylindrical filtration element are placed in the filtration unit. Quantity of the candles is selected to support required flow rate and duration between cleaning.

The filtration unit casing can be provided with customer specified inlet/outlet connections and additional instrumentation. Back washable units are provided with all equipment required for automated filtration and cleaning cycles.

Filtration quality

from 30 μm to 600 μm

Process temperature

from - 76°F to + 1500 °F

Max. Δp across filter element

up to 360 PSI

Max. Allowable Working Pressure

up to 29,000 PSI

Applications

- High temperature applications

- Corrosive fluids and gases

- Mechanical and thermal shock; vibration

- Mechanical and hydraulic impact on filter element

- Spikes in flow rates, pressure and contaminant properties

- Increased duration between replacement or cleaning

- Limited space

Industries

- Oil and gas industry

- Automotive

- Mining

- Power Generation

- Aero and space

- Shipbuilding, ballast water filtration

- Railway transport

- Sea water filtration

- Municipal